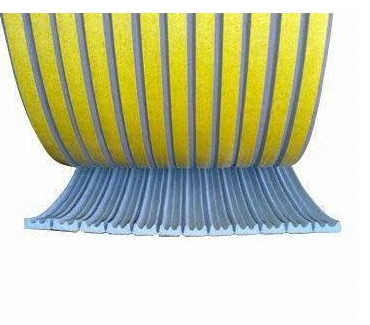

Self-adhesive Rubber Seal Strip,self adhesive rubber seals,rubber door seal strip,extruded rubber seal manufacture from china

[Our Rubber door seals Feature:]

1. High ozone resistance, anti-aging resistance, weather resistance,chemical resistance, UV resistance etc.

2. Good waterproof,shock absorption, dustproof, sound insulation etc.

[Self adhesive Rubber Seal Strips:]

Rubber Seal strips with damped, dustproof, insulated, waterproof soundproof,fixed functions etc, the sealf adhesive rubber seal is made by extrusion process and it made by high temperature microwave vulcanization, sealf adhesive rubber seals are widely used in many kinds of car doors and windows, including auto doors, gasket doors and windows, containers & other industries etc.

self-adhesive rubber seal strip

1. Used in door

2. High tensile strength, flame resistant

3. Virous shape available

self-adhesive rubber seal strip:

auto door rubber seal strip

Process is made by extrusion

Shape and size can made by the customer's requrement

[self-adhesive rubber seal strip specification:]

| Pruduct name | sponge rubber door seal strip |

| Material | EPDM |

| Producing way | Extrusion |

| Color | black,brown,grey,yellow,orange,pink,blue etc. |

| Hardness | 30-80 shore A |

| Tensile strengh | ≥10 Mpa |

| temperature arrange | -40°c ~ +120°c |

| Feature | high elastic,anti-ultraviolet,ozone proof,shock-proof,buffering,sound-proof etc. |

| Usage | various door seals etc |

[Our product's Application:]

Our rubber edge trims are widely used in many kinds of car doors and windows, including auto doors, gasket doors and windows, containers & other industries etc.

Our product test report followings,

|

Product name |

EPDM Foamed seal strip products |

||||||

|

|

|

|

|

|

|

||

|

|

number |

Test item |

|

Standard request |

result |

conclusion |

|

|

product

specificatisons |

1 |

appearance |

Qualified for test |

||||

|

2 |

Test item |

unit |

standard |

result |

Qualified |

||

|

3 |

Depending on the density |

g/cm3 |

0.65±0.15 |

0.6 |

|||

|

4 |

Tensile Strength |

MPA |

≥2.5 |

2.8 |

|||

|

5 |

Elongation |

% |

100-400 |

338 |

|||

|

6 |

|

Tensile strength |

% |

≥-15 |

-13 |

||

|

elongation |

% |

≥-25 |

-19 |

||||

|

7 |

Ozone-resisting(tear 20%,40℃/72h)

|

- |

No cracking |

No cracking |

|||

|

8 |

Brittleness temperature |

℃ |

≤-35 |

-38 |

|||

|

Conclusion |

Qualified |

||||||